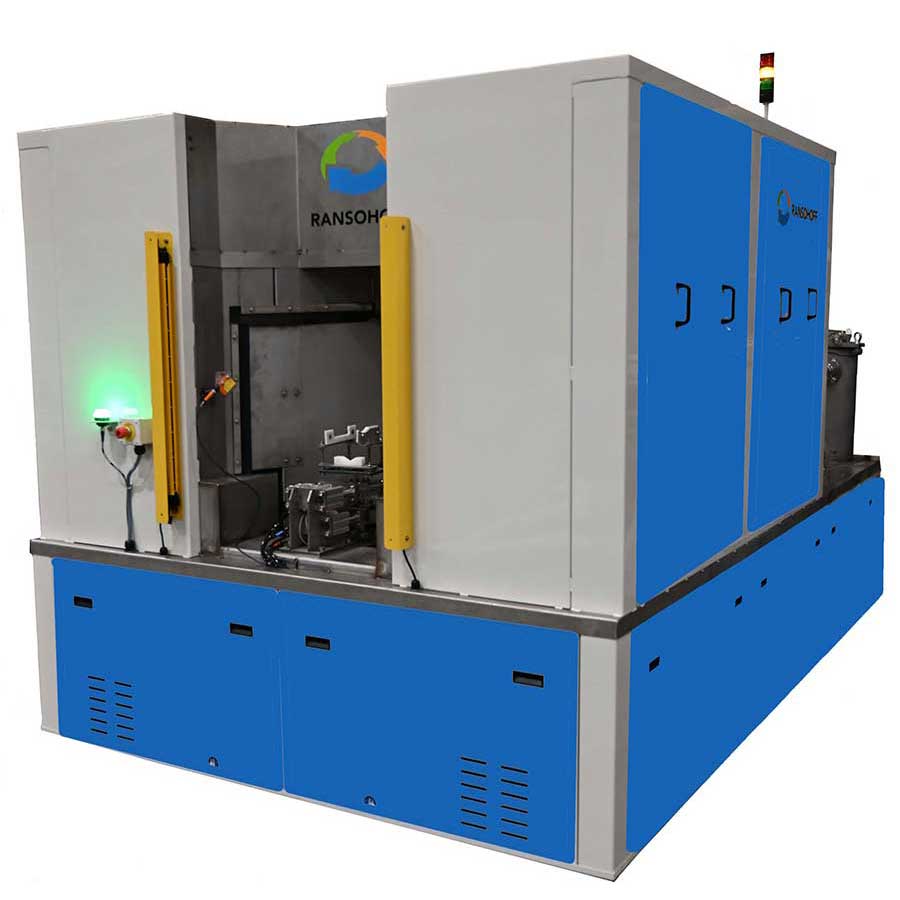

LeanJet® RT-18 Automated Rotary Index Table Parts Washer

The patented LeanJet® RT (Rotary Table) is one of a series of “Right Sized” and “Right Priced” cabinet washers specifically designed for use within lean or cellular manufacturing processes. Here’s an overview of its features and benefits:

Innovative Design:

- Patented Rotary-Table Design: This design eliminates work passage openings, preventing cross-contamination between stages. It also includes an inner stage part rotation feature, ensuring optimal cleaning and drying results.

Versatility:

- Multiple Configurations: The LeanJet RT cabinet washer is available with various wheel configurations, providing both wash and dry or wash, rinse, and dry capabilities.

- Accommodates Diverse Parts: It can handle a wide range of part sizes, weights, and configurations, making it a highly adaptable industrial parts washer.

High Performance:

- High Impact Sprays: Strategically positioned to ensure thorough cleaning of parts.

- High Pressure-High Velocity Heated Air Blow-Off System: Ensures efficient drying, reducing residual moisture and enhancing overall cleanliness.

Integration and Efficiency:

- Reduced Footprint: The compact design of this industrial parts washer allows for easy integration into small work cells, ideal for lean manufacturing environments.

- Flexibility: Its adaptable design supports various applications, making it an essential tool for maintaining cleanliness standards while optimizing space and resources in manufacturing setups.

In summary, the LeanJet RT (Rotary Table) cabinet washer provides an efficient, versatile, and space-saving solution for industrial parts washing, aligning perfectly with lean manufacturing principles through its innovative design and high-performance capabilities.

- Design Specs

- Optional Equipment

- Videos

- Case Studies

Design Specs

| Cleaning Sequence: | Wash & Dry (Rinse Stage Available) |

| Process Type: | Continuous |

| Production: | Up to 120 Parts Per Hour |

| Part Orientation: | Directly on Rotary Table or in Custom Fixture |

| Max Work Envelope: | 12” Diameter x 12” High / 18” Diameter x 18” High |

| Method of Loading / Unloading: | Manual or Automatic via Robot |

| Footprint: | 8” Deep x 6’ Wide x 6’-9” High |

| Cleaning Mechanisms: | Spray |

| Drying Mechanisms: | High Velocity Heater Air |

| Controls: | Programmable Controller and HMI Screen |

| Typical Applications: |

|

Optional Equipment

- Pro-Sep Oil Recovery Unit

- Heated Recirculating Rinse Stage (RT-18 Only)

- Heated Blow-off Stage

- Robot Load & Unload

- Custom Part Fixtures

- Stand Alone Vacuum Dryer

Gearing

Gearing Ring & Pinion

Ring & Pinion Cylinder Head

Cylinder Head