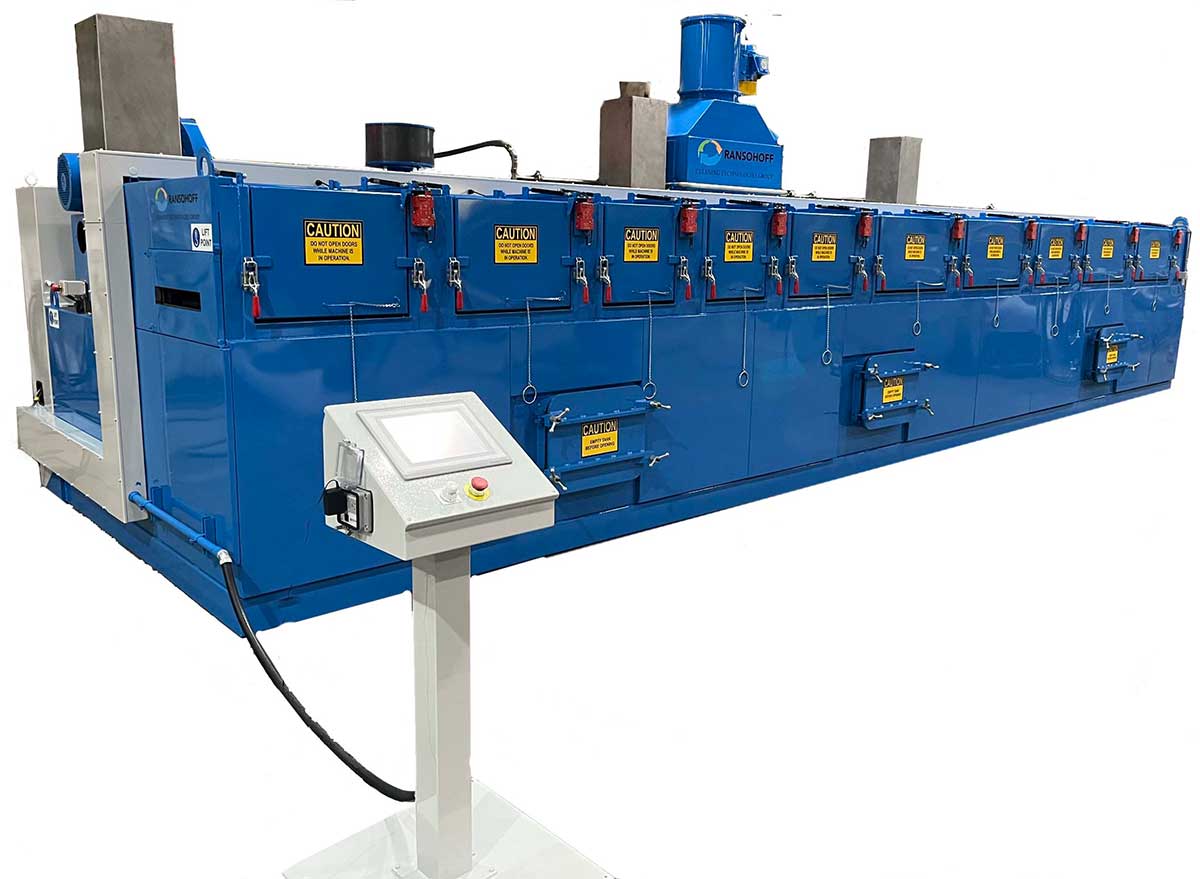

Continuous Strip System Conveyor Parts Washer

The Ransohoff Continuous Strip System is designed to be the most energy-efficient strip cleaning system available today. Tailored for lean manufacturing, this washer uses a practical approach to cleaning and water stripping. The system was developed with direct customer input, leveraging past successes to ensure quick and efficient access and servicing.

The Ransohoff Continuous Strip System is designed to be the most energy-efficient strip cleaning system available today. Tailored for lean manufacturing, this washer uses a practical approach to cleaning and water stripping. The system was developed with direct customer input, leveraging past successes to ensure quick and efficient access and servicing.

All stages of the washer are insulated and include individually adjustable exhaust dampers to minimize system heat loss. Its low-profile housing allows for easy access to the machine’s internals and provides a clear line of sight over the machine. The standard all stainless steel construction guarantees years of trouble-free service in even the harshest environments.

Designed for processing continuous strips of steel, the continuous strip system effectively removes mill oils and loose scale. It is engineered and manufactured to be flexible, durable, simple to use, and easy to maintain. Additionally, the strip cleaning system comes with the Ransohoff 3-2-1 warranty.

- Design Specs

- Optional Equipment

Design Specs

| Cleaning Sequence: | Wash, Rinse & Dry (Multiple Rinse Stages Available) |

| Process Type: | Continuous Strip |

| Production: | High Volume, High Speed |

| Part Orientation: | Directly on Flatwire Belt or Pulled though with the customers reel. |

| Max Work Envelope: | Up to 36″ Wide |

| Method of Loading / Unloading: | Automatic |

| Footprint: | Starts @ 10′ Long x 5′ Wide x 4′-6″ High (with 12″ work envelope) |

| Cleaning Mechanisms: | Direct Spray or Ultrasonics Immersion |

| Drying Mechanisms: | High Velocity Air and Pinch Rollers |

| Controls: | Relay Logic (Optional PLC / HMI) |

| Typical Applications: |

|

| Warranty: | Best in Class 3-2-1 Warranty |

Optional Equipment

- Enhanced Exhaust System

- Enhanced Solution Filtration

- Additional Recirculation Stage(s)

- Programmable Controller and HMI

- Cool-Down Stage